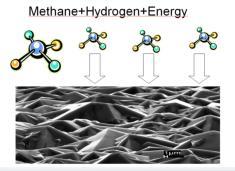

Nova Diamant use the Hot Filament Technology to grow CVD Diamond coatings – not to be compared to DLC (diamond like carbon). The method is relatively versatile and easy to adapt to different components compared to other technologies (microwave, arc jet). Hydrogen and a small portion of Methane are introduced in a vacuum chamber. A filament made of Tungsten is then heated to a temperature of more than 2100 C and activate the gas molecules. In a close vicinity of the filament diamond grow with a speed of 0.3-1 µm /h. During deposition the substrate has a temperature of 900 C which limit the amount of material that can be coated with diamond. A problem for some applications is the variation of coating thickness that the process normally cause. We chose to develop a rotating substrate holder which enables us to grow close to unlimited thickness of even coatings on demanding products like seal rings.

Diamond has

- Highest hardness of all materials 5x Sapphire

- Very Low friction

- Highest thermal conductivity

- Chemical inert in almost all environments

Which result in extremely good performance in

- Abrasive wear

- Erosive wear

- Corrosion

- Sliding contacts

- Dry sliding