Diamond coated face seals

- Virtually no wear

- Extended pressure and speed (PV values)

- Very high resistance against dry running and lack of lubrication

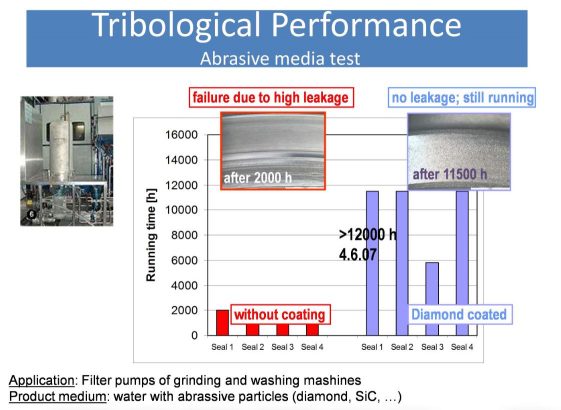

- Can be used in sever abrasive environments

- Increased time between service

Since 1998(i) CVD diamond coatings have been tested and evaluated for mechanical face seals. The results are stuning with very good performance in tough situations like dry running, lack of lubrication and abrasive media. The Diamond coating also enables extended PV values and energy savings for the mechanical seals. In addition the service interval can be extended substantially.

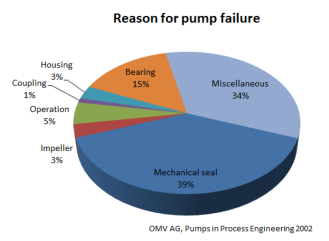

Today the mechanical seal failure contributes to a large part of the pump failures and service cost. The majority of the failures are due to dry running/lack of lubrication for the seal. Depending on the application, a diamond coating can result in a very short ROI and also be enabling in some severe applications. With constant improvement/development since the first published results i) of the technology, we know have the third generation of diamond coatings which is a reliable and show a very high performing solution for mechanical seals. Today we have many hundred successful installation in the world. The installation range from completely dry running to extremely severe applications with PV values of 70 MPa m/s in abrasive sub-sea installations. We also have installed seal rings that have been running for over 10 years in the pulp industry.

For many applications the reduced friction gives considerable energy savings for the user. Diamond coatings for face seals are a good choice in many applications but typically gives the best value in

- Oil, gas and multiphase applications

- Slurry applications – abrasive wear resistance

- Pharmaceutical industry – dry running

- Chemical industry – chemical inertness

- Hot water applications

- High PV values

Our unique technology which rotate the seal rings during diamond growth gives flat seal surfaces regardless of thickness. We can deposit diamond to very thick layers and still there are no demands for extra processing (lapping). We also have improved the adhesion to very high levels. Not only enough for normals use but also for extremely high loads.

i) Surface and Coatings Technology Volume 105, Issues 1–2, 5 June 1998, Pages 169–174

Typical results from some of our Diamond coatings. Comparable tests give significant differenses and the same good results are shown in real field applications.