Diamond balls/spheres

CVD diamond balls/spheres

We are proud that we now can offer Diamond coated ceramic balls with high degree of roundness and a very smooth Surface. They can be used in many different applications. It have been shown that spherical Surfaces with a Micro/nanocrystalline Diamond coating with roughnesses down to a few nm gives very low friction and no adhered material in sliding Contact with “difficult” metals like Aluminim and Titanium. (Wear 200 (1996) 225-232 and Diamond and Related Materials 7 (1998) 1471–1477)

We grow a layer of high quality microcrystalline CVD Diamond on top of a high grade ceramic ball (Typically G5 tolerances). The coatings have a very good uniformity and are then polished to a very smooth/shiny surface resulting in an almost perfect sphere of the hardest known material.

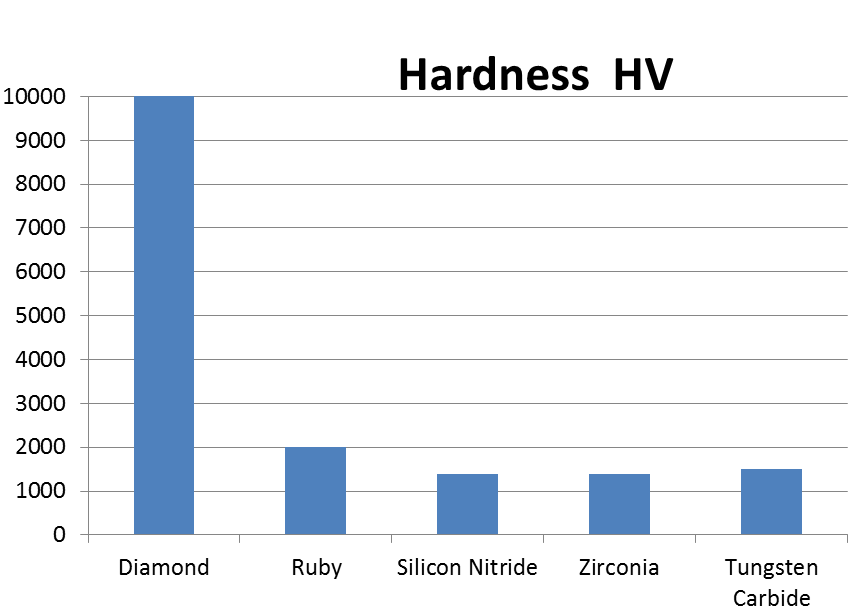

- The hardness gives a very wear resistant and Surface with huge improvements in wear resistance and lifetime of component.

- Another advantage of diamond is the inert surface. This is a great advantage in many applications like metrology and burnishing.

- Measuring tips / Probes – Great improvement in service life and significantly less material sticking to the surface.

- Burnishing – for a very quick and cost effective surface improvement

- Valves – less wear

- and many more

We produce on request but also have some sizes in stock which we can deliver on short notice.

Wear test

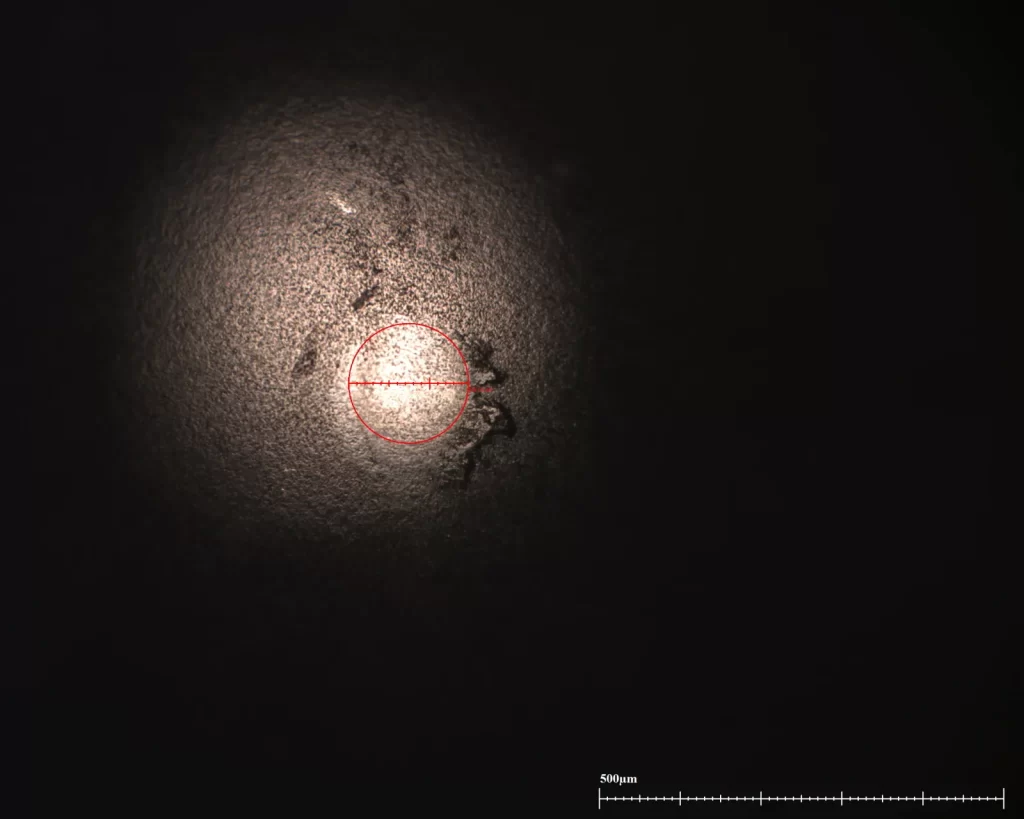

A Diamond coated Silicon Nitride ball was compared to an uncoated in a sliding test. The balls where sliding against a nitrided steel with a speed of 150 mm/s and normal force of 8N. After 6 minutes the Silicon nitride ball had a large wear mark. No wear could be detected on the Diamond coated ball. The test continued for 5 hours with the diamond coated ball and then a sligtly polished area could be detected (weak red ring around the wear mark). Still some of the roughness from the original Diamond Surface was seen indicating a polish of well below 50 nm. An attemt to estimate the wear rate showed that the ceramic Silicon Nitride ball was worn at least 2500 times as fast as the diamond surface.

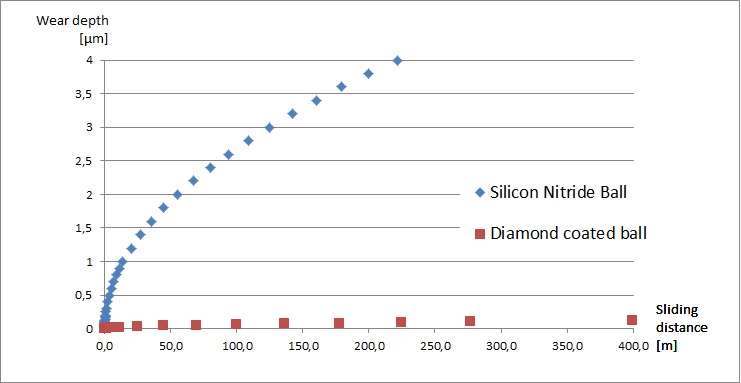

If a force of 0.1 N is used (Common) a probe quickly loses it’s tolerances and goes from a G5 to G10 after just 0.2 m of sliding distance.

Wear mark (slightly polished inside the red ring) on Diamond coated ball – 5 h sliding

Wear mark on Silicon Nitride ball – 6 minutes sliding.

The wear of a probe have a large influence on the performance of probing applications. In the figure to the right are an example how fast the tolerances are lost (wear rate) on a spherical probe if its sliding on one position. Already after a sliding distance of 0.9 m the wear correspond to an error of G10 (130 nm) tolerances. The diamond coated probe could slide 1700 m before showing the same error.

If an error of 1 µm is acceptable the ceramic probe last 14 m and the diamond coated probe last 27000 m.

Wear depth of a 3 mm ball with and without Diamond coating. Not how fast the ball loses tolerances when sliding with a normal force of 0.1 N and a point load.

Wear during longer sliding distances. The error due to wear will quickly be large and force replacements of the probe.

The Diamond surface is extremely inert and does not pick upp material in Contact to other materials. A test where aSilicon Nitride ball was sliding against Aluminium showed that it easily pick upp/adhere material, see picture. The same test with a Diamond surface showed extremely low amount of adhered material.

Diamond balls can be mounted by glue or vacuum brazing. A vacuum braze gives the best mechnical strength but is more complicated/costly.

A simple gluing procedure with an Epoxy gives good mechanical strength. A 3 mm Ball on a 2 mm stem easily manage a 20 N load.

Since the balls always have the same dimension they can be press fit in palce. This is a very rapid and low cost process.

Burnishing can be very cost effective (quick process) to reduce roughness and remove bad Ridges/roughness on the surface. It can be used on a part sliding against a rubber seal which favor a smooth surface or other applications. The Diamond ball gives an improved surface when pressed/sliding against a material. This is typically done on rods or tubes in the same set up as machining is done. As an example a ground axis was burnished with a diamond ball. There is a distinct difference between the ground surface and burnished surface which is easily felt with the Nail.

FAQ

Find answers to frequently asked questions. Save time and get the information you need.

We can diamond coat balls of silicon carbide and silicon nitride.

A simple rule of thumb is >2000 times carbide/ceramic which is what a typical lab test gives. However, it varies depending on the problem/application.

The balls are polished to a very high roundness depending on the area of use. Often they have G10 tolerances ie a maximum error of 120 nm from a perfect sphere.

The diamond surface is extremely inert but can be glued with ordinary Epoxy glues. If a more stable connection is needed, the balls can be vacuum soldered with active solder.